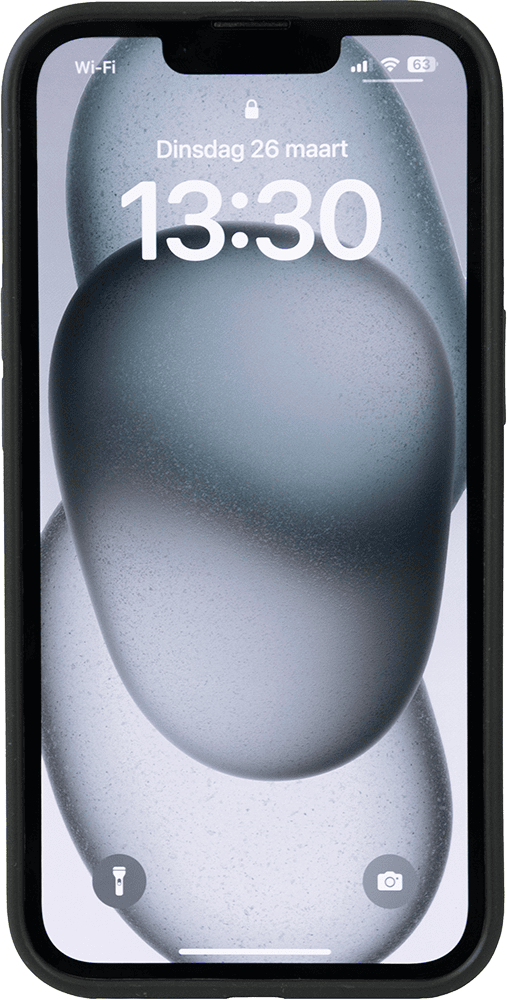

Eco-friendly

Biodegradable

soft phone cases

Sustainable solution for your webshop.

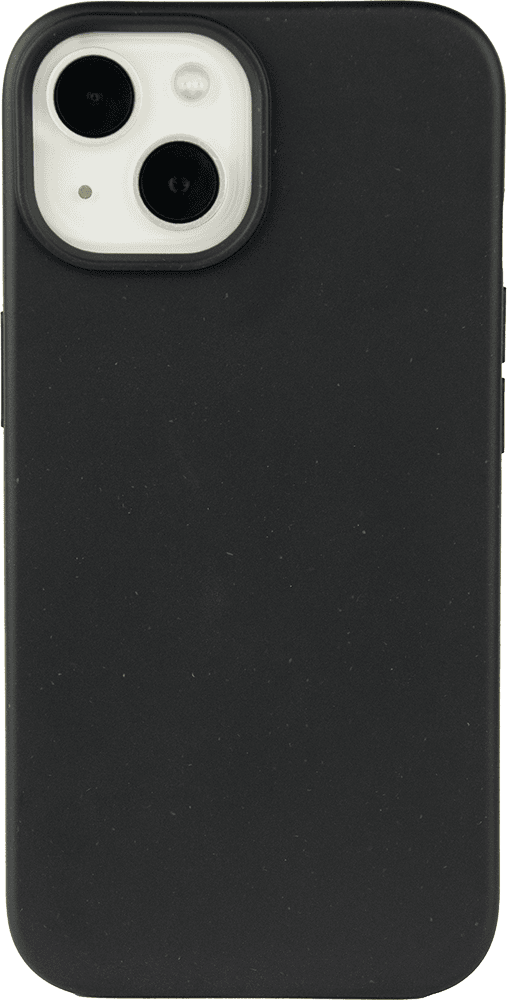

Introducing our line of eco-friendly custom phone cases. Choose sustainability without sacrificing style or protection with our biodegradable cases. Available in matte black, these soft cases are compatible with all iPhone models, Samsung S-series, and Samsung A-series. Made from a sustainable blend of wheat straw and TPU, these biodegradable cases are slightly thicker than our standard TPU cases and offer a unique matte finish. Plus, they’ll naturally decompose in moist environments within 18 to 24 months.

Our commitment

to a greener future

to a greener future

While we continue to explore new materials and printing techniques to further reduce our environmental impact, we are also committed to lowering our carbon footprint through optimized shipping services and sustainable packaging. Another key aspect of our sustainability efforts is the centralization of production and warehousing for the entire market. By utilizing a state-of-the-art stock prediction system, we efficiently manage our inventory, ensuring that no products go to waste and all stock is completely sold out.

Material composition

Our soft back biodegradable cases, crafted from 40% wheat straw and 60% TPU, are designed to decompose naturally in moist environments within 18 to 24 months. It’s important to note that the inks used currently are not biodegradable. We are dedicated to innovation and sustainability and are actively researching new ways to improve our products and processes. Our goal is to soon provide a fully biodegradable option for our custom phone cases.